Why COARSE sprays just work!

A visitor to our website wrote;

"How do any of your customers get a medium sized droplet at 60-70 lit/ha at 14-16 km/h?

We often don't want that size for drift purposes but the Agronomist wants medium for some chemicals..."

Dave comments;

Many operators, particularly those on 50 cm nozzle spacing's and using Air Induction nozzles, will never have a formally M rated nozzles on their boom at any time ever.

Does that mean they need be hampered from delivering a label compliant and efficacious volume of medium sized droplets into a dense canopy from their C rated nozzles? NO!

Does “Medium Spray Quality”, mean the same as “medium spray quality”?

If it is the case that you want to achieve a Medium Spray Quality because the label requires it, that may or may not be possible with the nozzles you have. However, according to regulations, M and above, including C, and VC etc. are still legally *compliant for use.

That is not to ignore that if a Chemical Manufactures has put M on the label and/or your Agronomist is recommending an M, then obviously an actual Medium Spray Quality nozzle would be ideal. Alternatively, the objective is to manipulate the droplet spectrum of the nozzle you do have to contain the highest possible percentage volume of medium droplets in the mix.

Let’s say the label says M. Your nozzles at the rate and speed you intend to spray may be C according to the chart. What to do?

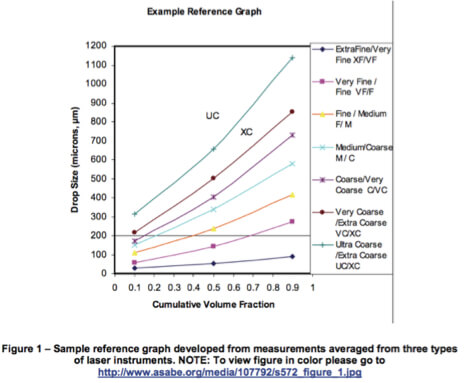

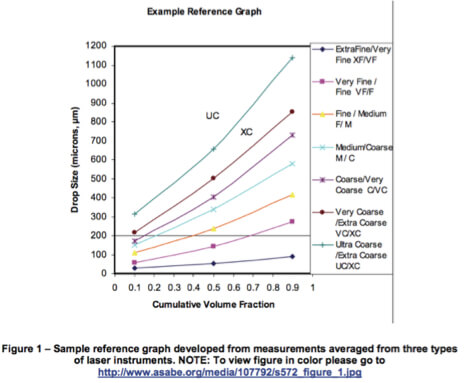

Firstly, understand that even low drift Air Induction Fan Nozzles produce a broad spectrum of droplet sizes. The current Spray Quality System is there mainly to provide a point of reference between Chemical Company recommendations and Nozzle manufacturers specifications for the purpose of drift control. For a thorough and detailed explanation on how the official Spray Quality ratings are derived, please read this article here: Explaining the Spray Quality Standard ASABE S572.1

The Spray Quality Rating therefore is a great guide to nozzle performance however the rating itself provides no objective data with which to calculate the percentage volume components of F, M, C, VC etc. for any given nozzle. In some cases, this information may be available from manufacturers, however since the current system has been in place, manufacturers tend not to publish the detailed data in their catalogues, merely the Spray Quality Table.

To illustrate the point, take a look at this table. It shows a different way of looking at Spray Quality compared to the tables that you will be used to seeing.

Follow the green line which is the 5 BAR curve. Note that it sits just on the Coarse side of the boundary between the Coarse and Medium rating without actually crossing it. If due to a small increase in pressure, the green line crosses over into the Medium zone, will that represent a wholesale change in the overall droplet distribution of the nozzle? Obviously not, although officially, it would have changed from a C to an M.

Conversely, if we opt for a more dramatic change in pressure. Consider a pressure increase from 3 BAR where on this chart the nozzle is a mid-range C up to 5 BAR which is still C, but as discussed above, on the cusp of M, moving the nozzle towards a more m’ish profile even though it’s not formally an M.

Again all of this is in the context of having an Air Induction nozzle that is not necessarily the formal Spray Quality that you would like it to be.

So, if you desire a medium spray quality, either because your label recommends a Medium Spray Quality and your nozzles are not officially M, but C or VC, there’s nothing stopping you from increasing your rate (label dependent) and pressure in order to push your droplet spectrum towards a more m’ish droplet mix to get the job done today.

Alternatively, if your label says C, you know that you can remain formally in the C category for compliance purposes, while going for a more m’ish spray quality for better penetration and coverage in dense canopy anyway. So far as in canopy action is concerned, you’ll have it covered either way!

Back to our website visitor, who like many operators is using a set of TTJ60 Twin Jets in 02 YELLOW operating from 3-4 BAR for his desired rates and speeds. That is a good nozzle choice from the formal Spray Quality perspective as it conveniently straddles the M/C boundary!

All good with that, except to say that the general assumption about twin-fans providing better penetration than flat fan's into canopy is an assumption that we have difficulty agreeing with.

Our customer by comparison, in the same situation would typically be using C rated 015 CFA or CFA-T Stubble Jets at 5-7 BAR. The "C" rating is fully compliant* for use with chemical products rated for M application, they're producing a practical working volume of medium droplets in the mix, AND providing excellent drift management compared with a pre-orifice nozzle.

We believe that would provide superior penetration than any brand twin-fan (including our own) in any kind of canopy, and sufficient medium droplets in the mix to deal with most pests.

Finally a topical comment from our friends Tom Wolf and Jason Deveau at sprayers101.com

"Use the coarsest spray that you can afford to. This will make application safer, it will widen the weather window, and it will simply let you get more done in a day or season. Coarse sprays work."

Maybe that has something to do with the quantity of medium's that come along for the ride ;)

Regards,

Dave Young

Reference:

- Australian Pesticides and Veterinary Medicines Authority - Spray Drift Labelling

https://apvma.gov.au/node/958