110° nozzles on spot-sprayers - Really?

With camera-based spot-spraying systems like Bilberry and See & Spray (which are capable of both single nozzle and multi-nozzle spot-spraying) gaining popularity, it appears to be common practice for operators to use the 110-deg nozzles that come standard with the sprayer.

We don't need to talk about 110° nozzles in single-spot. I think everyone gets that it's NO! But I do see room for a conversation about using 110° nozzles in multiple nozzle modes; side safety, buffer, etc., depending upon the brand of sprayer to which your camera system is fitted.

Typically, there will be groups of three or more nozzles activating together. Think of those as independent mini booms. Full rates occur between the overlapping nozzles with rate calculation based on nozzle spacing. Like normal!

The outer edges of those mini booms are where the problem lies. We call them the wasted edges. That bit where there is no overlap. A 110° nozzle at 70 cm height, the normal minimum operating height required by the cameras, has a footprint (spray width) of two full meters on the ground.

The total wasted edges per mini boom activation works out to twice the nozzle spacing. That's 100 cm (1 meter) wasted on 50 cm spacings, 76 cm wasted on 38 cm spacings, and 50 cm wasted on 25 cm spacings accounting for overlap. The more nozzles engaged in the mini boom, the lower the waste as a percentage of the total swath, but those pesky wasted edges are still there.

An 80° nozzle at 70 cm height has a footprint (spray width) of just over one meter (1.17 m). Surprisingly, the wasted edges are close to the same as the 110°. The important difference though is that the chemical concentration at the edges will be higher with the 80° than the 110°. Same volume, smaller footprint (spray width). You just need to think of the edge nozzles as if they were single-spot nozzles.

The prevailing thought appears to be that 110° nozzles are OK in multi-spot. The edge bits probably take out small targets missed by the cameras, and so they may. Is it fair to ask though, that if wasted edges are delivering half rates of active product on small unseen weeds, might that actually end up an unexpected contributor to herbicide resistance?

- By using 80° nozzles instead of 110° on 50 cm spacings in multi-nozzle mode spot operations, you're increasing the concentration of active product at the edges by 41.5% (110°-2m, 80°-1.17m).

- Similarly, using 40° nozzles instead of 110° on 25 cm spacings in multi-nozzle mode, you're increasing active product concentrations at the edges by 74.5% (110°-2m, 40°-0.51).

- If you're already using 80° nozzles on 25 cm, a switch to 40° will yield a further 56.4° improvement on that! (80°-1.17, 40°-0.51)

Reasons enough to switch?

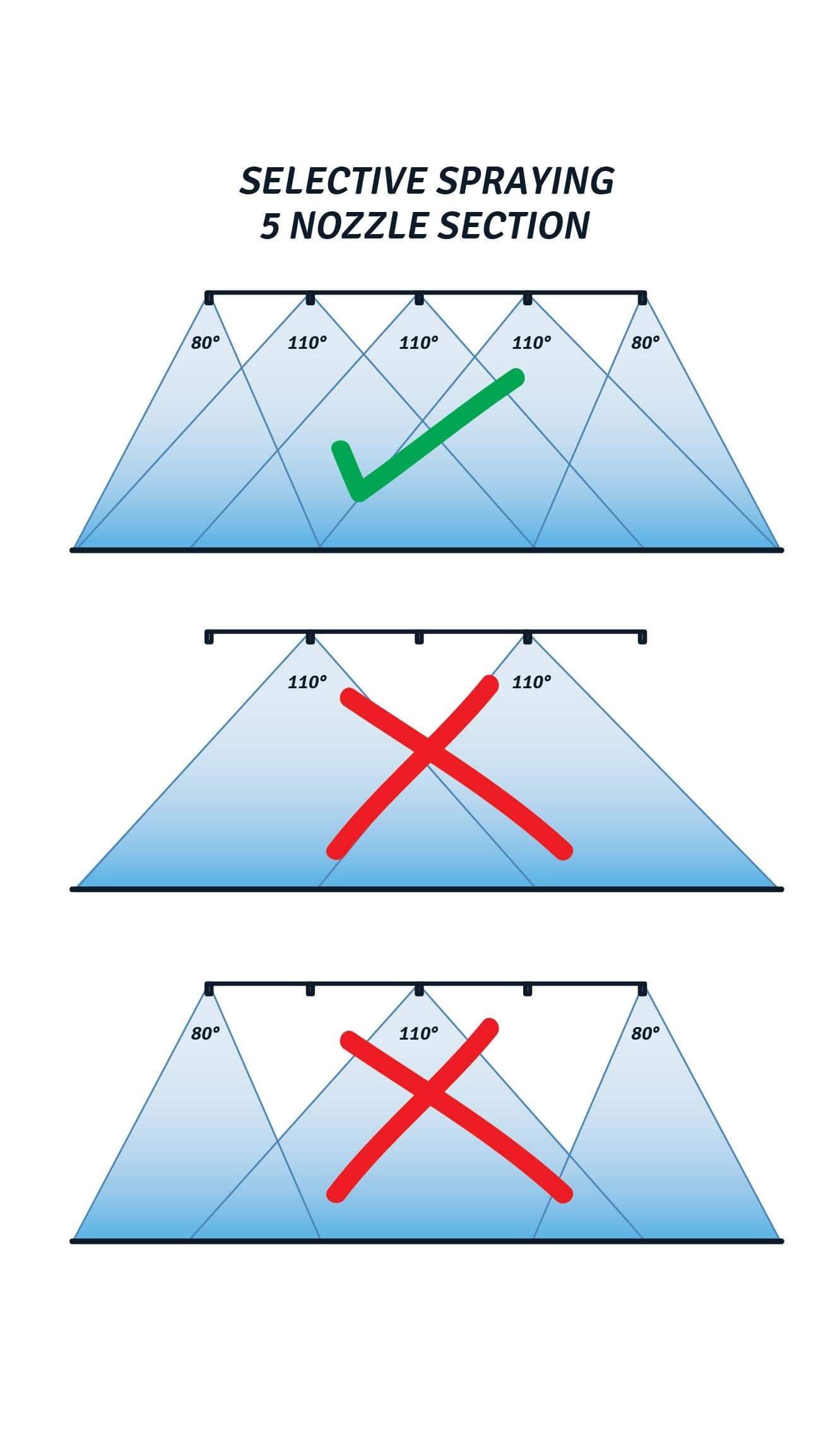

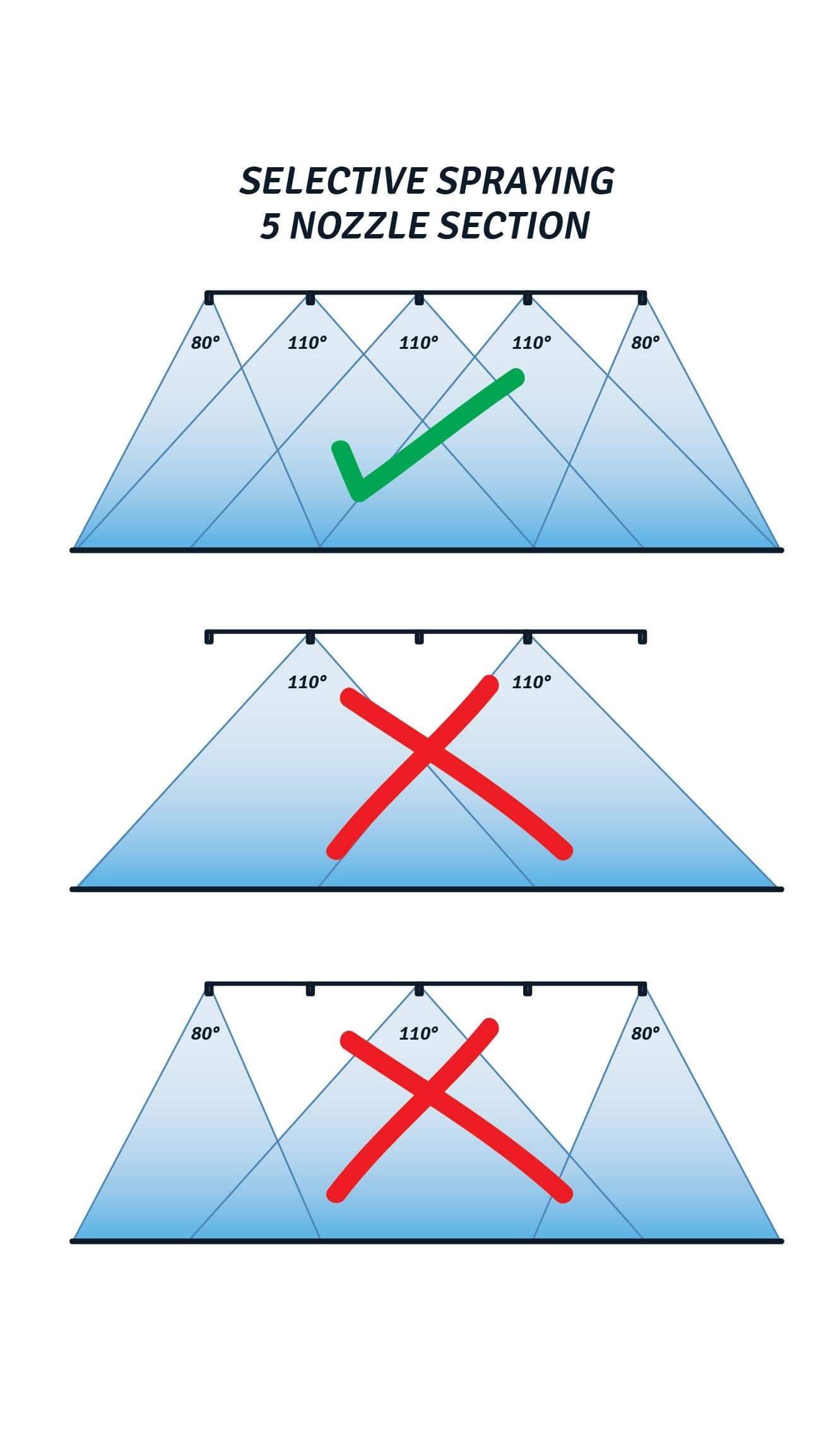

In cases of full boom section activations of five or six 110° nozzles (selective spraying as opposed to spot-spraying), a convenient fix would be to fit 80° nozzles to the section ends, eliminating the wasted edges altogether.

The other way to eliminate wasted edges is to go single-spot. But realize that will require different and much bigger nozzles.

My advice to anyone who asks is that 110° nozzles and spot-spraying, even in multi-nozzle mode, just do not go together. Why nozzle manufacturers make narrow-angled nozzles and call them spot spray nozzles ;)

Although there will always be exceptions, 80° on 50 cm spacings and 40° on 25 cm spacings are a good guide. That's what you'll find recommended in our various Apps where we have done all of the arithmetic and geometry for you. You can download a custom App to suit your specific equipment for FREE at https://appcentral.online

Article by Dave Young

1 October 2023